Zinc Oxide Manufacturing and Its Growing Demand Worldwide

n, often called ZnO, is a simple compound used as a healing medicine in ancient times. Early Indian records also described zinc oxide as a soothing treatment for skin. Over time, the material slowly moved from traditional remedies into large-scale industries.

Main Methods of Zinc Oxide Manufacturing

Modern factories rely on three major methods to create zinc oxide efficiently. Each approach fits specific raw materials and supports different industrial needs worldwide.

- The French Method

This method focuses on producing very clean and high-quality zinc oxide powder. Manufacturers heat high-grade zinc metal until it turns into hot zinc vapor. That vapor enters a chamber where oxygen helps form tiny white zinc oxide particles.

Factories prefer this method for cosmetics, medicine, and personal care products. Strong control over size and purity makes the final material very reliable. Because of rising demand, this process earns most global zinc oxide revenue.

- The American Method

This method uses zinc ores or leftover industrial materials instead of pure metal. Factories heat these materials with carbon sources like coke inside large furnaces. Zinc escapes as vapor and reacts with oxygen to create zinc oxide powder.

Lower costs make this option popular for recycling zinc-rich waste materials. However, higher impurity levels limit usage to rubber, ceramics, and heavy industries.

- Wet Chemical Production Method

This process avoids high heat and relies on controlled chemical reactions instead. Zinc compounds form inside water solutions before turning into solid particles. Workers filter, dry, and heat the solids to create finished zinc oxide powder.

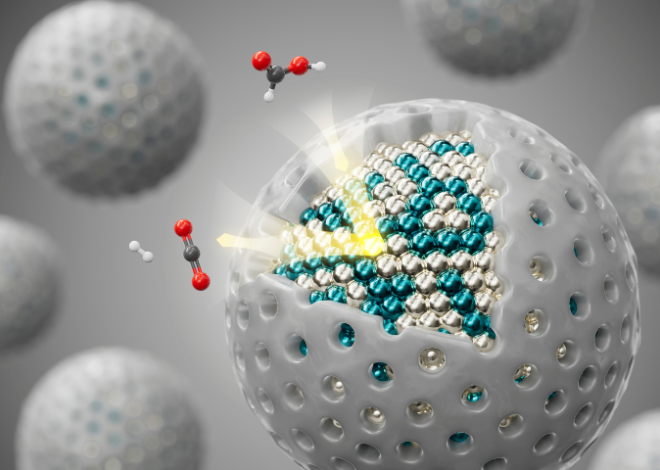

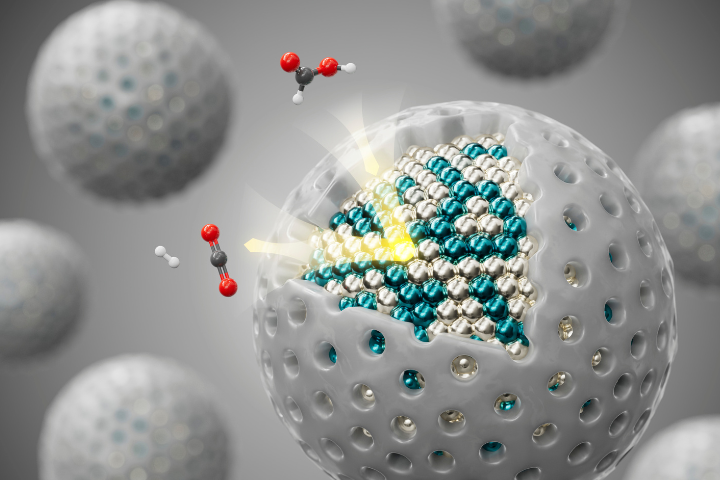

Excellent control allows producers to design special shapes and tiny structures. Advanced industries often use this method for research and modern technology products.

Growing Market Driven by Many Uses

The zinc oxide market continues to grow steadily across many industries. In 2023, the total market value reached around 5.5 billion US dollars. Demand rises across the transportation and healthcare sectors. Several studies predict the market could nearly double within the next decade.

Future Innovations

Scientists continue exploring new zinc oxide shapes at extremely small sizes. Nanostructures show promise in electronics, energy storage, and environmental cleanup technologies. Asia-Pacific dominates the market because of its large manufacturing activities.

China and India lead production thanks to strong rubber and ceramic industries. Meanwhile, North America and Europe focus on high-purity specialty zinc oxide products.

Zinc oxide is still relevant from ancient medicine to modern industry. Improved zinc oxide manufacturing methods help meet growing demands across many sectors. Future innovation will likely expand zinc oxide uses even further.