Zinc Oxide Production Process for Laboratory Activities and Its Chemical Structure

The zinc oxide production process for laboratory activities is carried out using wet, direct, and indirect chemical methods. This produces a white powder with a hexagonal crystal structure, which is used for research. It has the property of controlling particle size. So what is the explanation?

Zinc Oxide Production Process

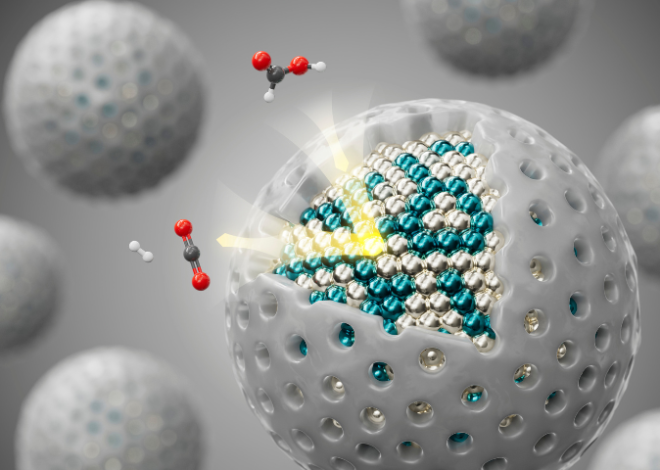

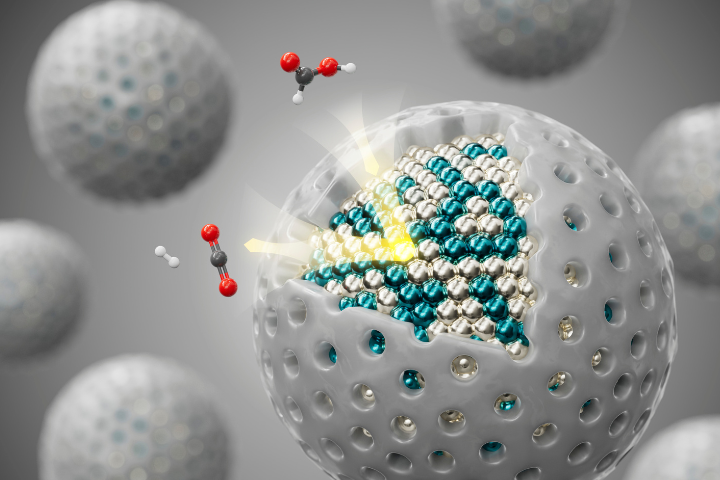

Zinc oxide is an inorganic compound widely used in industry. It is insoluble in water but readily dissolves in acids. This makes the zinc oxide production process for laboratory activities, especially in nanoparticle synthesis. The ZnO structure features strong ionic-covalent bonds between Zn²⁺ and O²⁻, which contribute to the formation of a stable hexagonal wurtzite crystal lattice. Its production involves three processes:

- Direct Method

Better known as the American Process, in which zinc metal is melted at 907°C to produce steam. This steam then reacts with O2 (oxygen) to form fine ZnO powder, which is collected. This is suitable for large-scale industrial production, producing high-purity zinc oxide.

- Indirect Method

Known as the French Process, its manufacturing principle is almost identical to the American Process. The only difference is that zinc is extracted from ore, which is then processed into pure metal. The steam is then oxidized to achieve the desired industrial yield.

- Wet Chemical Method

This involves several steps:

- First, a zinc salt solution such as ZnSO₄ (Zn(NO₃)₂) is added to water.

- Next, a base solution of NaOH or NH₄OH is slowly added to precipitate the zinc hydroxide.

- The precipitate is then filtered, washed, dried, and heated at a specific temperature to obtain the finest zinc oxide.

This process is suitable for precise particle size control, making the synthesis useful for all types of laboratory scales.

Physical and Chemical Properties of Zinc Oxide

In the zinc oxide production process, it has the chemical and physical properties of mixed cubic and hexagonal wurtzite. It is most commonly used because it is stabilized by growing zinc oxide on a substrate that acts as a center with a primary role.

Zinc oxide is a soft gas with a Mohs scale of 4.5, lower than III-V semiconductors. Its high capacity and conductivity offer many advantages for laboratory activities.

Conclusion

More than 50% of zinc is used in all types of industries. It is used as a buffer layer and vulcanization of rubber with citric acid. It’s sometimes added to concrete during processing to improve water resistance. Through the precise zinc oxide production process, its use in laboratory activities can be carried out smoothly.